Vacuum Electrical-powered Interfaces: Spaning the Divide Between Atmospheric Conditions

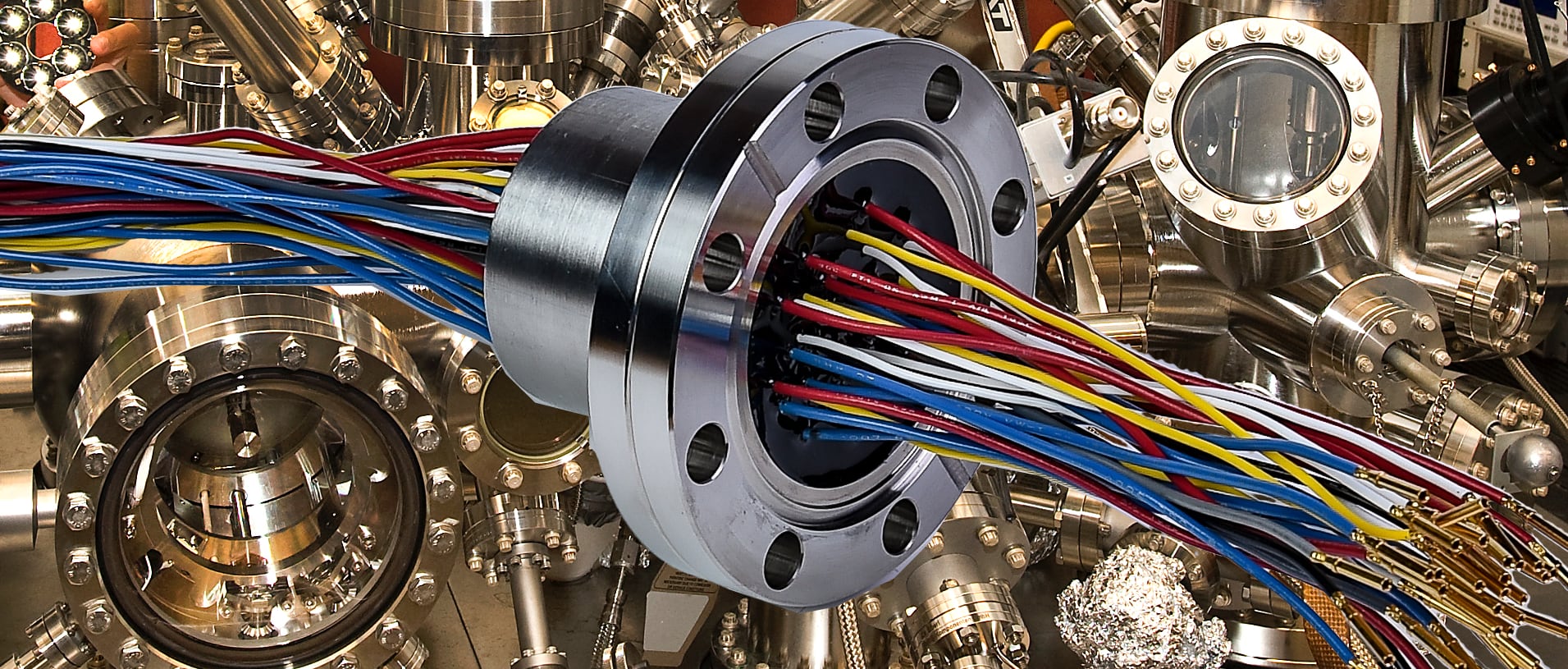

In a world where precision and management over environmental conditions is crucial, vacuum electrical feedthroughs play a vital role in bridging the gap between different environments. These specific components are engineered to facilitate the passage of electrical signals and power while maintaining a vacuum environment on one side and allowing for connections to external conditions on the other. This distinct capability makes them indispensable in multiple applications ranging from scientific to manufacturing processes.

Vacuum feedthroughs serve as a critical interface, ensuring that delicate equipment can operate effectively without jeopardizing the integrity of a vacuum system. By allowing for the seamless transfer of electrical energy, they allow advanced technologies to work in regulated conditions, providing researchers and engineers with the reliability they need to explore new horizons in their domains. Understanding how these components work and their importance in modern technology is crucial for anyone involved in fields that demand stringent vacuum environments.

Comprehending Vacuum-Sealed Feedthroughs

Vacuum-Sealed electric connectors are dedicated components that enable electric currents or energy to be transferred into a vacuum-sealed environment while preserving the continuity of the sealed environment. This is essential in many uses where electrical links need to engage with processes under vacuum conditions, such as in particle accelerators, vacuum chambers, and highly efficient scientific instruments.

The construction of electrical feedthroughs commonly involves the use of insulating materials and sophisticated closure techniques to stop any gas or other pollutants from breaking the seal. Common materials include ceramics and glass, which offer excellent electric insulation and can endure the rigors of the vacuum. These feedthroughs must be engineered to accommodate the unique electric requirements of the use while guaranteeing durability and reliability.

The importance of vacuum feedthroughs is paramount as they serve as a pivotal interface between the external surroundings and vacuum systems. By enabling safe and efficient electrical links, they help optimize efficiency in various industrial and research environments, facilitating advancements in technology and scientific discovery.

Applications and Advantages

Vacuum electrical feedthroughs are essential components in a variety of industries, allowing the transfer of electric signals and power between vacuum systems and outside environments. In research and development, such as particle colliders and vacuum chambers, these components ensure that sensitive electronic devices operates without interference from environmental factors. Their ability to maintain a controlled environment while providing reliable electrical connections makes them indispensable in experiments that demand extreme conditions.

In the industrial sector, vacuum feedthroughs are widely used in chip manufacturing processes. They enable the inclusion of electrical components within vacuum deposition systems, ensuring that high-precision technologies can operate efficiently. By facilitating connections for heaters, thermometers, and regulatory systems within a vacuum environment, these feedthroughs contribute to process efficiency and product quality.

The advantages of vacuum electrical feedthroughs extend to the aviation and healthcare fields as well. Equipped with sturdy designs, these feedthroughs provide dependable performance in extreme environments, such as outer space or high-vacuum applications. This reliability translates to enhanced safety and efficacy in critical systems, where electrical integrity is paramount. Overall, the use of vacuum feedthroughs promotes innovation and effectiveness across various sectors, highlighting their significance in contemporary tech.

Design Considerations

When creating vacuum electrical feedthroughs, it is essential to consider the materials used for the insulating material and the conductive elements. Insulators must have elevated dielectric strength and low outgassing properties to ensure the stability of the vacuum environment. Common materials include ceramics and specialized polymers, which are chosen based on their heat stability and suitability with the vacuum conditions. In addition, the conductive materials need to have high electrical conductivity and resistance to oxidation, often using metals like steel alloy, copper, or gold plating.

The geometry of the feedthrough is a critical aspect. The design must minimize potential points of failure by avoiding acute angles or complex shapes that could create stress concentrations. Engineers often prefer streamlined designs that facilitate easier installation and maintenance. Clearances between the feedthrough elements and the vacuum chamber must be meticulously measured to prevent arcing or electrical shorts while ensuring that the feedthrough is snugly placed within the designated space.

The methods of sealing play a vital role in the overall efficacy of vacuum feedthroughs. A reliable sealing approach is necessary to protect against leaks, which can jeopardize the vacuum environment. Welded, glass-sealed, and epoxy methods are standard; the choice depends on the specific application and operational requirements. Ensuring that the feedthrough remains sealed under varying temperature and pressure conditions is paramount to its long-term performance.